Posted by Jason Lillywhite

Managing water in the Western United States is a complex challenge, especially in shared reservoir systems governed by the "prior appropriation" doctrine. This legal framework determines who gets water, and when, based on their legal rights and the ever-changing natural water supply. Dynamic simulation is a tool that enables you to better understand this type of system and visualize its behavior, leading to clearer insights and more reliable predictions.

his guide outlines a methodology for simulating shared water rights within a reservoir using dynamic simulation, applicable to various modeling environments. While the concepts are demonstrated using an example model built in GoldSim (with full details and the model available

Conceptualizing the Reservoir Model

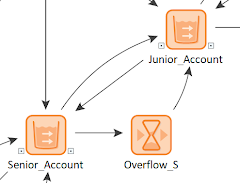

The main part of the model represents a single physical reservoir broken up into a series of virtual "accounts." Each account stands for a different water right holder or purpose, and they're stacked in order of priority:

- Dead Pool: The absolute base, ensuring minimum operations. It gets water first and holds onto it longest.

- Senior Account: Represents an older, high-priority right (like for established farms).

- Junior Account: A more recent right (perhaps for growing cities).

- Conservation Account: For environmental needs or simply as the "overflow" bucket for any excess water the reservoir can hold.

|

| Representation of the storage accounts. |

These accounts actively track their own volumes and maximum capacities, giving us a clear picture of who "owns" what within the shared reservoir at any moment.

When new water comes in, it must be allocated to each account based on its priority. Also, common losses like evaporation need to be fairly shared among all accounts. The model requires that senior rights get their water first, which often means junior accounts have to curtail deliveries or even give up some of their stored water to satisfy those with older claims.

Incorporating Water Rights Rules into the Simulation

Here are useful modeling techniques for simulating shared water rights in a reservoir:

Cascading Bucket Filling

To implement the "first in time, first in right" principle for water allocation, incoming water is sequentially allocated:

The highest priority account is filled first.

Once an account reaches its capacity, any surplus water "spills over" to the next highest priority account.

This process continues down the hierarchy to the most junior account.

This cascading mechanism is typically repeated daily to ensure continuous prioritization of water distribution based on established water rights.

Senior Right Fulfillment

In scenarios where a higher-priority account experiences a storage deficit, the model must facilitate water transfers from junior accounts to satisfy that senior account's requirements. This simulates real-world water transfer agreements, where junior users might temporarily hold water that can be "called upon" by senior users when needed.

|

| Screen capture of the shared water rights GoldSim model |

Managing Shared Losses (Evaporation)

Reservoirs incur water losses due to evaporation. To accurately model this, calculate the total evaporation for the entire reservoir. Then, proportionally distribute this loss among all active accounts based on their current water holdings. This ensures that all water right holders share equitably in the losses.

|

| Screen capture of the evaporation loss sharing component |

Addressing Dynamic Interdependence

Modeling Water Delivery and Demand

Each account withdraws water from its allocated "bucket" to meet its specific demands. Due to the priority rules for filling and senior right fulfillment, junior accounts are inherently more susceptible to water scarcity. Simulation results typically show that conservation flows, often the most junior, are the last to commence and the first to cease.

It's important to note that a junior account might, at times, exhibit a larger outflow than a senior one. This phenomenon reflects the "use it or lose it" principle prevalent in prior appropriation, which incentivizes right holders to utilize their water for a beneficial purpose (even if that purpose is a specific environmental flow) to maintain their water right.

|

| Main Result plots showing account volumes and deliveries |

The Utility of Dynamic Simulation

By explicitly tracking ownership and applying legal rules to day-to-day operational decisions, dynamic simulation clarifies how water rights translate into practical water management. The flexibility in dynamic simulation platforms for defining components and their interactions over time makes them particularly well-suited for constructing such water allocation models.

We encourage you to explore the full model and its documentation on our Knowledge Base: Water Rights in Shared Reservoirs – GoldSim Help Center